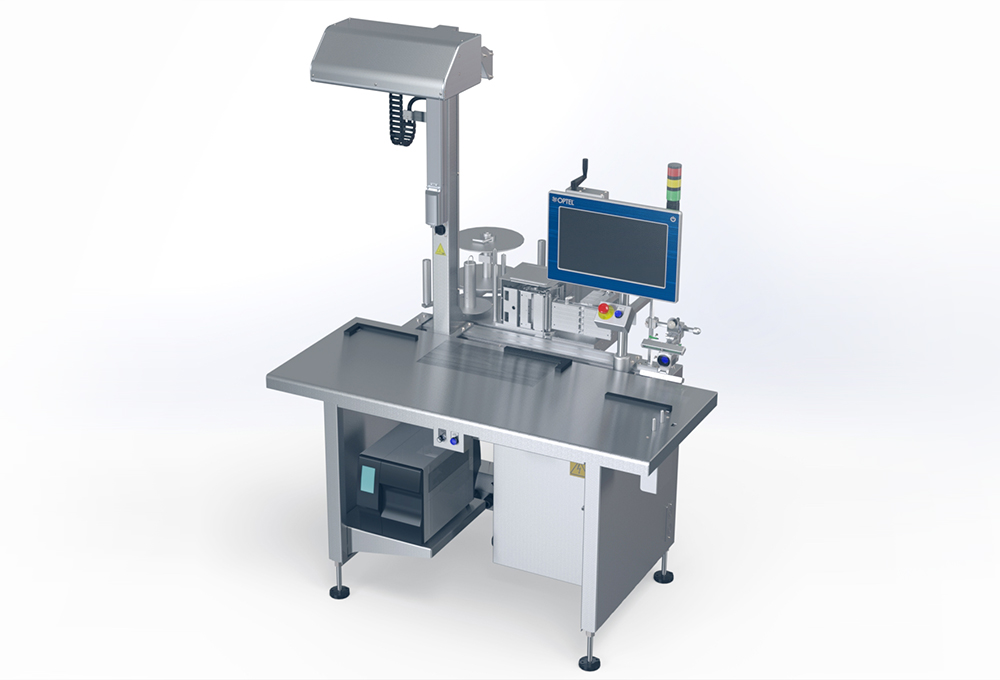

SEMI-AUTOMATED AGGREGATION SOLUTION

The PackStation™ SAP (Semi-Automated Packing) allows efficient aggregation of serialized items to a serialized parent in accordance with GS1 standards.

KEY FEATURES

- Serialization and aggregation of carton/bottle/bundle to case

- Audit trail and batch trail event logging

- Simple user interface

- Color-coded LED indicator for ergonomic efficiency

KEY BENEFITS

- Compliance with regulations

- Minimal training and easy operation

HOW IT WORKS

Items are inspected at the first station to ensure they are valid before packing them in a case. After the item inspection is successful, an integrated Print-and-Apply system automatically applies a label on the parent container and this newly printed label is inspected to complete the aggregation.

Visual indicators are present for both children and parent inspection stations to confirm the inspections are successful or defects have been identified. If defects are found, the PackStation™ SAP has features to prevent the operator from sending the defects to the next step of the production process.

With this setup, the PackStation™ SAP increases your manual packing speed and connects to OPTEL’s LineMaster™ in real time in order to verify and report the serial number. OPTEL’s unique barcode-reading technology gives you the most efficient reading, ensuring maximum performance of your packing operations. The station supports both GS1 serial number formats.

PackStation SAP

DOWNLOADRelated Solutions