WHAT THE REUSABLE PACKAGING MANAGEMENT SOLUTION CAN DO FOR YOU

SOLUTION OVERVIEW

The Reusable Packaging Management (RPM) solution offers many options depending on your company’s needs and goals. The difference resides mostly in the type and amount of data monitored and the number of touchpoints in the supply chain.

The RPM solution uses data capture technology and powerful software for real-time data empowerment and visualization. Assets can be tracked using a unique identifier (UID) printed directly on the asset or label or an RFID or NFC that can be read by Internet of things (IoT) devices. These technologies can be combined for additional data monitoring (cold chain, temperature, freshness, consumption, etc.).

The technology stack needed for each option is similar: packaging identification (UID), camera, RFID reader, cloud database and mobile app.

KEY FEATURES

OPTEL’s RPM solution was developed in partnership with leading brands. Key features were required for the solution’s success in the food, beverage and agrochemical industries:

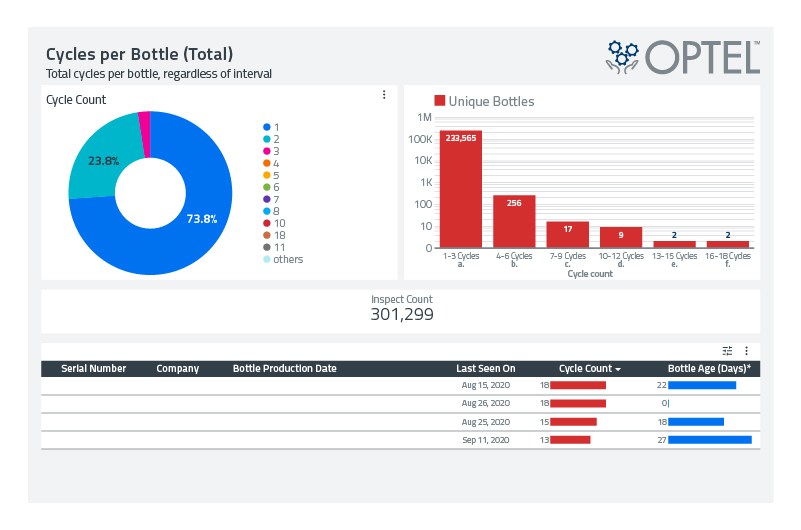

- Real-time visibility on your asset fleet: dashboards and alerts

- Monitoring and mapping of asset locations, distributors and internal transfers

- Geolocation of items

- Tracking devices/methods make the solution damage-proof and economical

- Simple and automated data collection

- Optional customized metrics monitoring

- Interoperability with existing systems (ERP, API, WMS)

- Valuable analytics: asset age, losses, durability, return rate, scuffing level and more

TRACKING AND OPTIMIZING THE LIFE CYCLE OF REUSABLE REFPET BOTTLES

Coca-Cola FEMSA Case StudySuccess Story

RELATED SOLUTIONS

Optchain Solution

OPTEL’s Intelligent Supply Chain is a powerful traceability platform that digitizes supply chains from end to end.

Carbon Tracking

Measure and track your environmental footprint across your supply chain

Inventory Tracking and Planning

Manage your inventory like never before: real-time visibility on asset inventory levels, geolocation and expired date tracking

Operational Efficiency

Optimize your production efficiency with strong analytics and reliable, real-time data for the agribusiness